14 Jul Offshore Vessels: Optimising fuel consumption

Written by Anouar KIASSI, CEO of Ascenz Marorka

Saving energy during the lifecycle of oil/gas fields and windfarms is of increasing concern due to impacts on OPEX and the environment. Ascenz Marorka’s EFMS can help tackle these issues.

In most oil and gas fields, the fuel consumed by the offshore vessels is provided and paid for by the oil and/or gas major. Thus, there is little to no incentive for the crew to save the fuel beyond some contractual thresholds. In some cases, the malpractices can go beyond the poor performance of the vessel and include fuel pilferage.

With an unmatched experience of more than 20 years in Electronic Fuel Monitoring Systems (EFMS), Ascenz Marorka (the new brand combining Ascenz and Marorka) has developed a large portfolio of innovative digital solutions that tackle these issues with proven results. Our EFMS is approved by the largest oil majors such as ExxonMobil, Saudi Aramco and Petronas.

With the environmental requirements growing, the accurate monitoring of fuel consumption and energy optimisation features are important to achieve the economic and environmental objectives of oil & gas organisations.

It all starts with precise measurement

Ascenz Marorka was the first technology company in Singapore (and in the world) to introduce a digital bunkering monitoring solution using mass flow meters (2012). Indeed, as the opposite of all the other types of flow meters, the mass flow meter is unaffected by the flow profiles. For example, the concerns arising from changing temperature, viscosity, and pressure conditions are eliminated to deliver higher accuracy and reliability. With no moving parts, the mass flow meters are adapted for the harshest marine conditions.

Flowmet mass flow meters (an Ascenz Marorka brand) are perfectly designed for reliable and accurate measurements under challenging conditions. Accurate and reliable measurement is the starting point of any kind of vessel performance management initiatives.

Bunkering monitoring

Bunkering monitoring often takes place at the point of custody transfer, where the transferred quantity can be confidently quantified according to the purchase contract. Usually, mass flow meters are used to ensure quantity and quality of the flow transfer. The digital monitoring of the entire bunkering process with real-time data collection and artificial intelligence coupled with operational experience can limit errors, negligence and malpractices. In this process, Ascenz Marorka acts as the third party of confidence to increase transparency and accountability of the commercial transaction.

In fact, malpractice can occur in many ways, such as cappuccino bunkers with excessive flow aeration, tampering with pipelines and seals, interference with the meters using magnets, contamination of fuel with water, and use of uncertified or faulty flow meters.

In addition to technology, the entire system performance is guaranteed by proper meter selection and installation, acceptance tests and extensive checks of mechanical, software, electrical and operational security. For example, equipment is sealed against unauthorised adjustment, tampering or dismantling; software onboard is protected against any unauthorised change, data collected during the bunkering process is stored securely onboard and in the cloud for many years to be visualised or to support claims if need be, and critical alarms are activated in real-time if there is any suspicious behaviour.

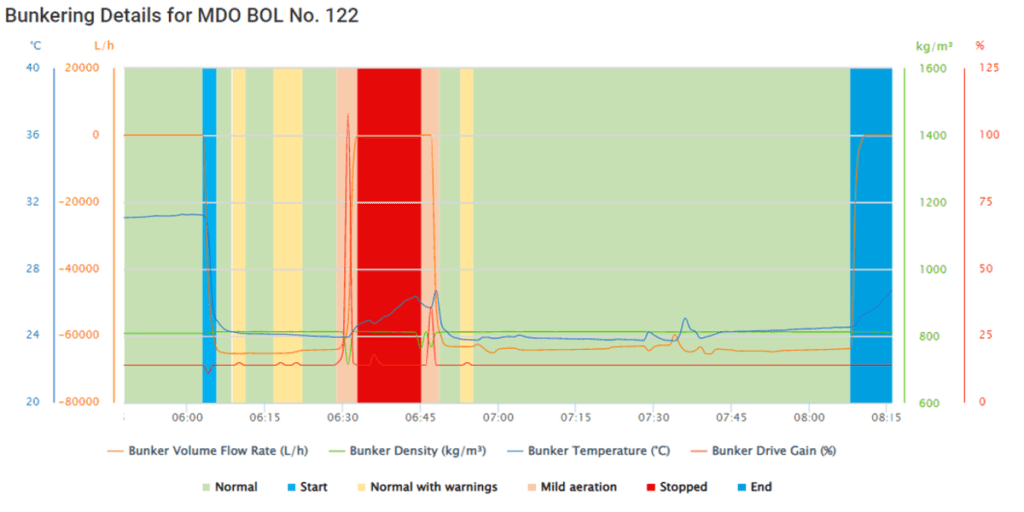

The system provides a full view of bunkering activities including key parameters such as mass flow rate, density, temperature and drive gain. The Smart Bunkering feature is more than a mere visualisation of the situation. It offers a valuable analysis throughout the bunkering process using state-of-the-art artificial intelligence.

Here are a few use cases:

Thanks to proper bunker monitoring, some of our customers have reported savings of up to USD 400,000 in six months.

In 2022, an independent study conducted by the consulting company BLUE Insight revealed that ‘short bunker deliveries’ remain prevalent in Rotterdam and Fujairah – with the issue likely to be exacerbated by the prospect of new, more expensive low carbon fuels entering the market. The study concluded that about 3% of the bunkers in the second largest port in the world recorded as delivered were never actually pumped on the ship. Also, 80-90% of the survey respondents recognise the issues outlined (i.e. bunker quantity problems).

While waiting for the regulators to impose the use of mass flow meters for bunker suppliers, the receiving vessels can already take action and install a mass flow meter on the bunkering line combined with a robust digital bunkering monitoring solution. Ascenz Marorka has delivered hundreds of these in the past years all around the world, and the demand is growing in Europe.

Fuel consumption monitoring

The first KPI most ship operators would look at is the daily fuel consumption. It is indeed an important indicator especially if it is defined in the charter party.

However, without the operational context, it is hard to derive actionable insight from this data to save fuel. In fact, every vessel activity or operational phase will have a different consumption profile. Thus, it is not surprising to see the consumption varying during the day, or from one day to the other.

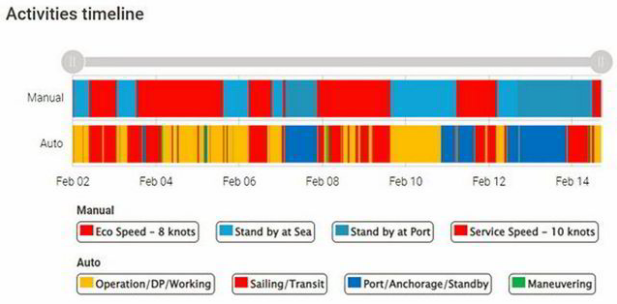

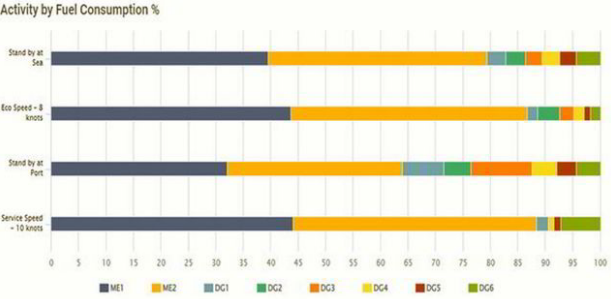

One of the means to add context to the analysis is to breakdown the consumption by vessel activity. Automatic data collection provides a lot more information and greater granularity to improve operations in addition to reducing the human bias. Using artificial intelligence to break down the vessel activities gives more accuracy and insight to the ship owner and the operator.

Below is a comparison between the vessel activity breakdown done automatically and manually.

This way, the operator can differentiate between comparable phases and see if the fuel is used for the most productive (or value-generating) activities.

This analysis can be taken further by looking at other parameters like the weather or the number of engines running.

Manual data vs. automatic: case studies

The tradeoff between relying on manual data or auto-logged data for vessel performance analysis is a recurrent topic in the maritime industry. However, the amount at stake, in terms of fuel and emissions, advocates for the adoption of the most reliable solution, which is automatic data collection.

Use case: one of our customers decided to install EFMS on one of their offshore support vessels showing unexplained high fuel consumption manually reported. A full Ascenz Marorka EFMS was installed to automatically measure bunker intake, main engines consumption and auxiliary engines consumption. The difference in reported fuel consumption and measured fuel consumption showed an average difference of 52.8%, which is about USD 0.5M/vessel/year. The pay back in this case was only a few months with an impressive ROI.

Speed optimisation

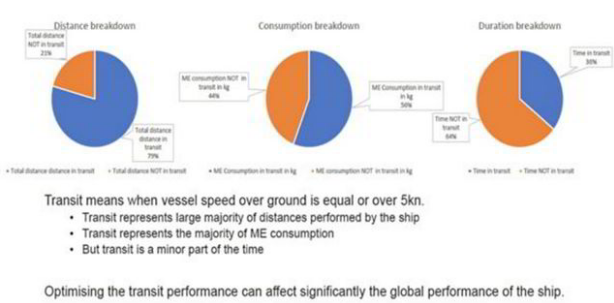

Most offshore supply vessels spend a significant amount of fuel in transit. Thus, optimising this phase can lead to important savings.

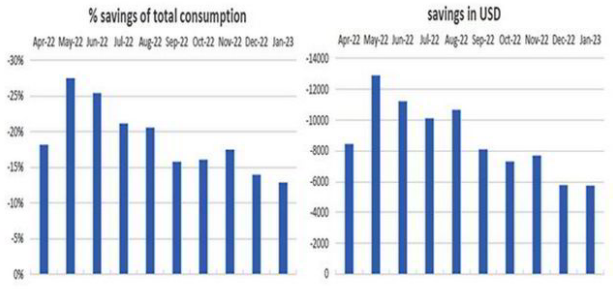

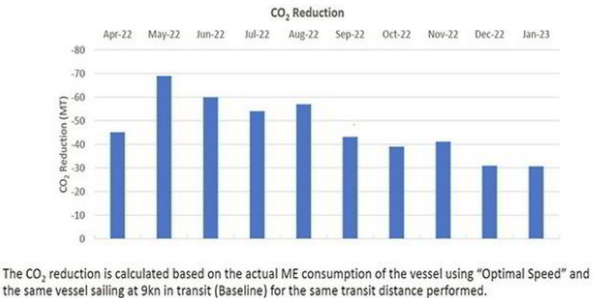

Here is an example of a vessel that we have been monitoring for many months.

Based on the vessel specification and a limited amount of historical data, our artificial intelligence algorithm advised the right speed for the crew to adopt during the transit phases. The configuration takes into account the flexibility required to respect the operations planning and objectives.

In the use case mentioned above, the savings obtained were significant.

Anti-tampering features

The standard way to protect the equipment onboard from human interference is to seal the enclosures and the flow meters with anti-tampering tapes during the commissioning. Ascenz Marorka has designed features that go beyond and provide advanced protection and real-time surveillance of the integrity of the system. For example, innovative (patented) sensors are put on the bolts to detect when flanges, pipes or hatches have been opened. Also, a camera put inside the enclosures detects any unauthorised opening.

In addition to these physical measures, Ascenz Marorka EFMS implements high standard cyber security rules to prevent any virtual threat on the confidentiality or integrity of the data and the overall system.

Conclusion

The offshore market is expected to grow steadily in the coming years. This growth is driven by the positive world energy outlook and the fast development of alternative offshore energy fields, like windfarms.

Saving energy during the lifecycle of an oil/gas field or a windfarm is an increasing concern. Not only because it reduces the OPEX, but also because it reduces the overall project environmental impact.

The Ascenz Marorka Electronic Fuel Monitoring System provides unique innovations and an unmatched experience in this domain; giving customers tangible results.

Find the latest news on Ascenz Marorka :

GTT Website: https://gtt.fr/