28 Jun Sloshing Virtual Sensor to optimize tank maintenance

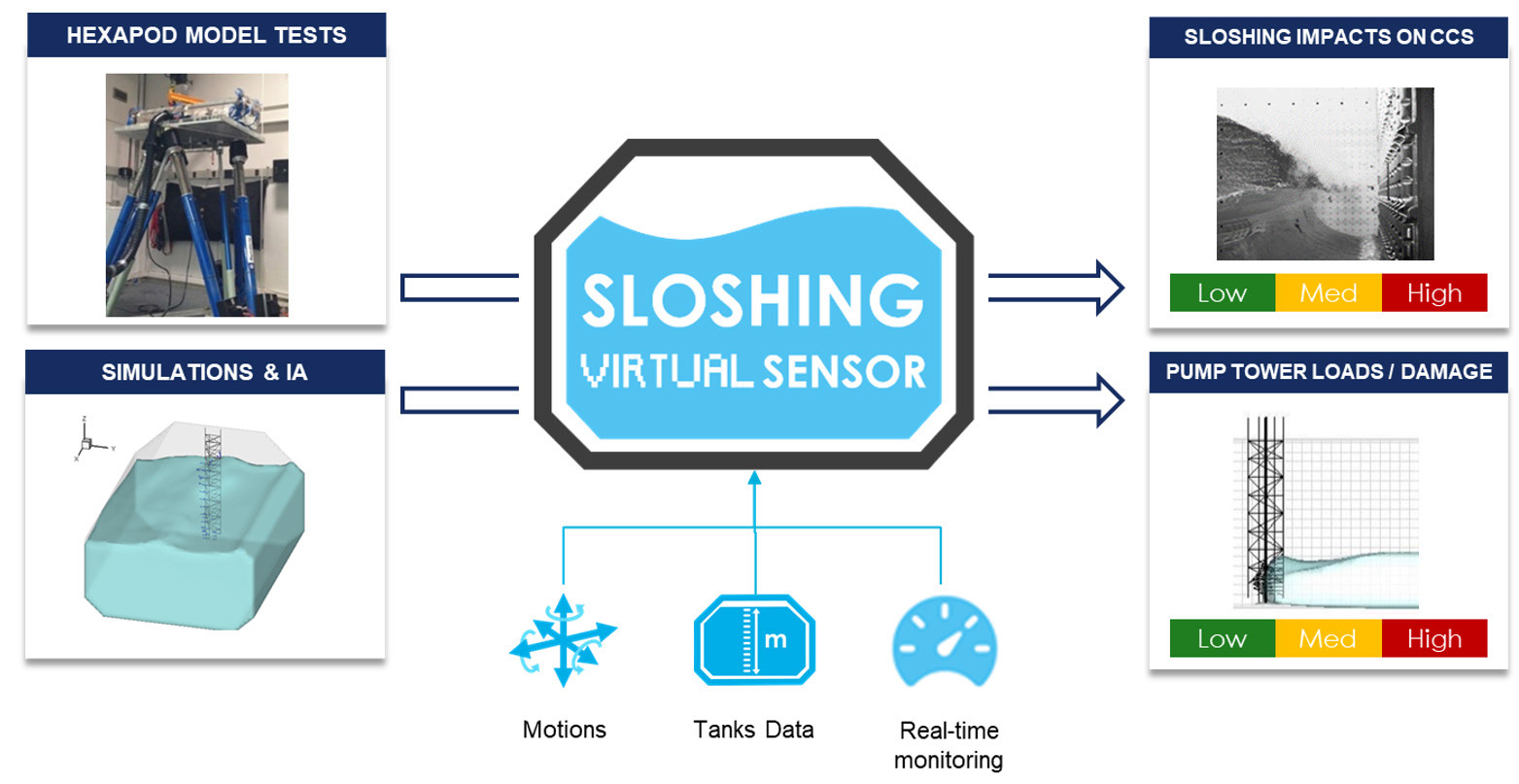

On worldwide shipping routes, LNG tanks sometimes face harsh weather conditions. Sloshing virtual sensors inside LNG tanks can create high loads on the containment system. GTT has developed tools to quantify it and even predict it at sea. This methodology can be applied not only for voyage management, but also for predictive maintenance of the tanks.

Methodology

GTT’s researchers leverage machine learning techniques from our motion analysis platform (see picture). The resulting function behaves like Virtual sloshing sensors. The KPIs are made accessible to clients via dedicated solutions in order to support decision-making for:

- Sloshing management at sea

- Fuel gas pump tripping prevention at sea

- Tank maintenance

Combined with GTT’s IoT platform, a robust onboard data acquisition, these features are supporting ship-owners in their daily operations, giving them, more than ever, an eye in the tank.

Sloshing prediction

Prediction of sloshing activity at sea is key parameter for efficient voyage management. While containment systems are well designed to sustain the impacts of liquid motion in tanks (sloshing), sloshing activity may nevertheless be significant. The cargo motion is not only a safety matter; it also has an impact on the ship performance.

GTT has developed a tool to characterize the liquid motion activity from weather forecasts. Two main characteristics are estimated, the sloshing frequency and the sloshing pressure, which can be derived to define a sloshing intensity.

This predicted sloshing activity, can nurture mitigation actions, such as change of speed or course, if required (or tank to tank transfer operations for offshore units).

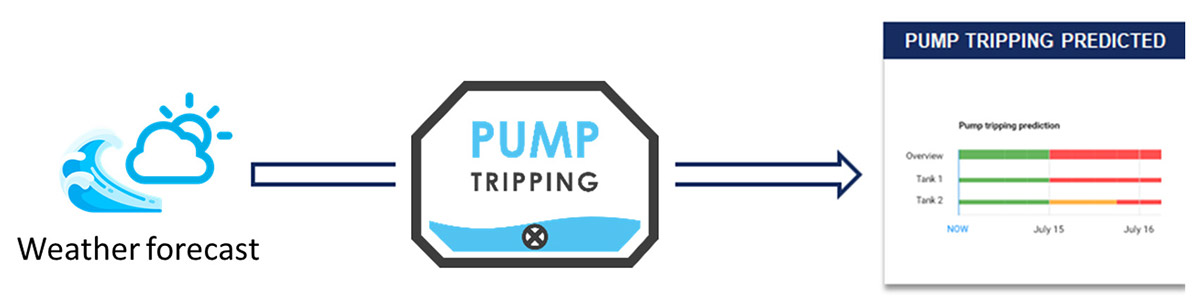

Pump tripping

In the context of LNG fueled ships, fuel gas pumps in the tanks must be fed with liquid continuously.

The pump tripping, a situation in which the minimum liquid level above the suction head of the pump is not respected, may induce cavitation. Due to the acceleration of the liquid in the pump, the pressure can significantly decrease which may lead to the formation of the gas bubbles. This liquid phase change can generate shock waves in the pump power system and possibly create damage.

GTT has developed a digital solution to predict the risk of pump tripping for very low filling levels of liquid in the tank, when the ship is confronted with harsh sea conditions.

This tool, trained on refined numerical simulation results, can predict the risk of pump tripping for each tank on the planned route, based on the sea condition forecasts.

From this prediction, crew can then elaborate mitigation actions, such as enabling fins (if available on the vessel), change the vessel’s speed or course, or adjusting the flow-rate of the pumps.

Virtual Sloshing Sensor to optimize the tank maintenance

Alternative inspection plans aim at increasing vessel utilisation and reduce downtime. In fact, a credible alternative to the regular inspection and maintenance cycle applied to LNG membrane tanks can lead to important savings and greater operational flexibility.

By combining risk analysis and the latest digital technologies, GTT offers effective tools to answer that objective without sacrificing the safety and the reliability of LNG tanks.

In the framework of an Alternative Survey Plan, the list of indicators to monitor is defined along with the associated thresholds and criticality of each trigger. More importantly, a digital system, combining an MRU and IoT platform provides the full range of data required to monitor the tanks continuously and optimize tank entries.

Our unique fatigue prediction algorithms and the collected data enable the Sloshing Virtual Sensor. Trained on a large scope of operational conditions of Sea States or Motions and loading cases (Draft, filling level…) seen by the ship, it derives the relevant indicators allowing informed decision-making regarding inspection optimisation. This is applicable to both the containment system and the pump tower (fatigue and strength).

In addition, all necessary critical parameters are monitored in real-time. Abnormal deviations are automatically detected by our supervisory rules and double-checked by the officer on duty in our 24/7 monitoring center. If any risk is confirmed, the Customer is promptly informed.