31 Aug LNG Vessels: Digital solutions for sloshing management

Written by Anouar KIASSI, CEO of Ascenz Marorka

The membrane tanks in LNG carriers are designed to support sloshing loads in all conditions. Yet proper sloshing management requires digital tools to optimise maintenance cycles, the boil of gas and reduce risks.

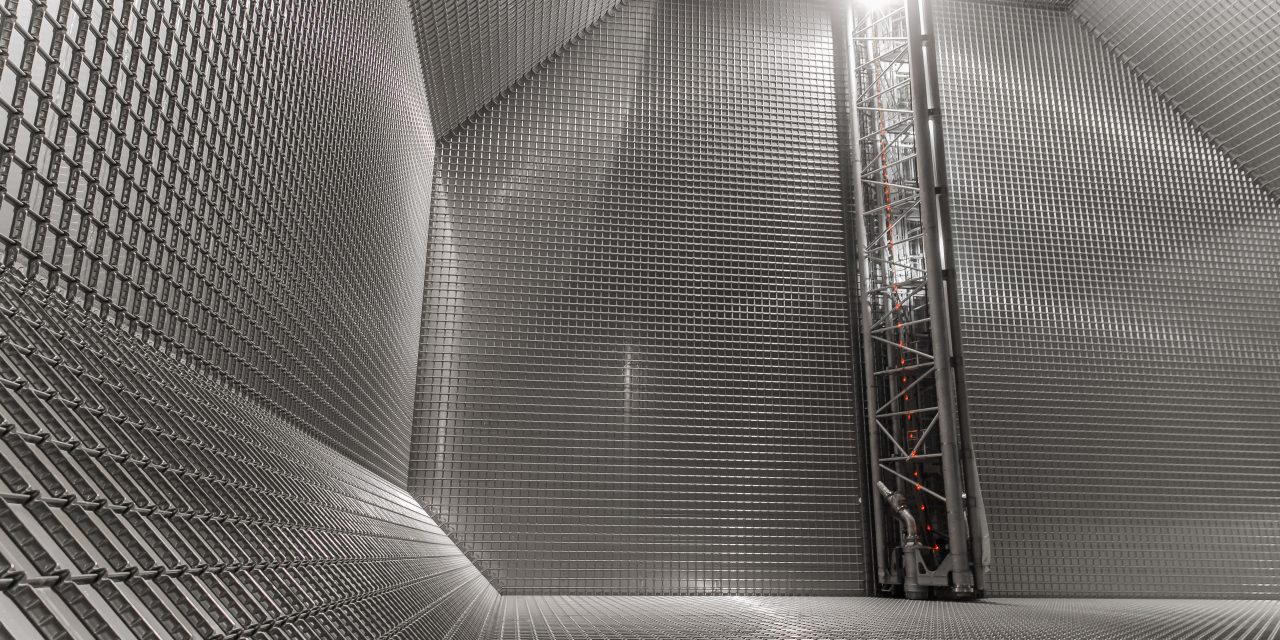

The GTT Cargo Containment System (CCS) is directly fitted on the inner hull of the ship and LNG is in contact with the insulation system. However, when a tank is not 100% filled, the liquid inside it can move. The liquid impact on the insulation system resulting from this movement is called sloshing.

Sloshing description

Sloshing can be described globally and locally. The local behaviour depends on local factors like the escape/compression of gas, condensation, shock waves, fluid/structure interaction and free surface instabilities, to name a few. These factors are hard to predict in a deterministic manner. This is the reason why sloshing is considered a stochastic phenomenon that is modelled in a probabilistic manner. The local effects induce a high variability of loads. The global behaviour depends on environmental factors (mainly sea-states), the ship design (ship geometry/seakeeping, cargo tank geometry, tank position, etc.) and operational factors (ship loading characteristics, the tank’s filling level, ship/wave incidences, ship speed, etc.).

Sloshing effects

The direct mechanical effect of sloshing is the impact it has on the Cargo Containment System. This leads to local loads against the primary membrane which cause banging noises and increases the probability of high pressure impacts. Another mechanical effect of sloshing is the drag forces it induces on the pump tower. In addition, severe sloshing also has thermodynamic effects as it increases boil-off gas, resulting in increasing pressure.

Digital tools for sloshing management

Crews manage sloshing based on heuristic indicators (e.g. banging noises) or unsubstantiated assumptions which produce uneven results. Thanks to GTT’s unique expertise in sloshing, Ascenz Marorka provide innovative digital solutions to manage sloshing in an effective manner with tangible benefits.

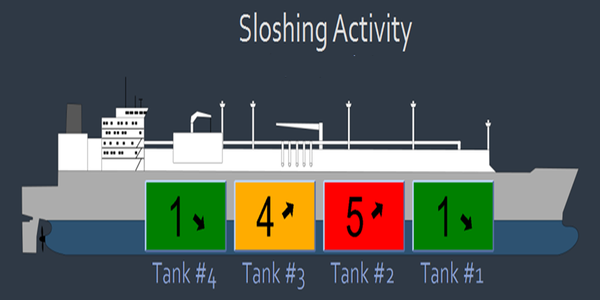

● Real-time monitoring (SloShield):

Sloshing impacts induce vibrations in the tank structure with a recognisable ‘signature’. By adding sensors around the tanks, the SloShield constantly monitors the vibrations in each tank to isolate these ‘signatures’ from the rest of the signals. This allows the crew to identify the sloshing activity and its evolution, in real-time. In fact, by detecting the early signs preceding the establishment of a severe sloshing situation, the crew can mitigate the effects by changing the speed or the course of the ship, for example.

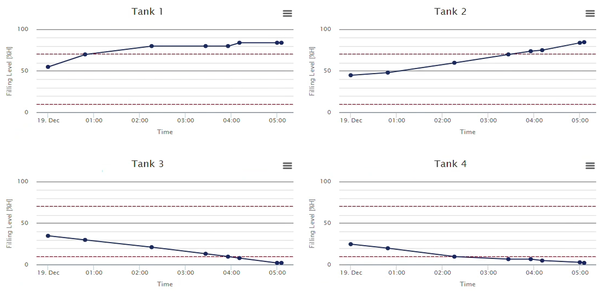

● Emergency departure management (Emergency Departure):

Unloading or loading cargo can sometimes be jeopardised by a sudden external risk like harsh weather conditions or an issue at the receiving/loading party. The potential negative effects of sloshing are high when the tanks are only partially filled. GTT & Ascenz Marorka’s Emergency Departure tool helps the crew reach a safe filling level by suggesting tank-to-tank transfer sequences.

The sequence can optimise or minimise the time spent in an unsafe configuration, or optimise the autonomy of the vessel.

● Sloshing prediction (Sloshing Virtual Sensor):

GTT & Ascenz Marorka’s Sloshing Virtual Sensor characterises the liquid motion activity from the weather forecast. This was made possible thanks to hybrid models trained on GTT’s unique sloshing database. The two main characteristics estimated are the sloshing frequency and the sloshing pressure. The combination of both helps derive the sloshing intensity.

CONCLUSION

LNG carriers’ membrane tanks are designed to support the sloshing load in all conditions. However, Ascenz Marorka’s digital tools can provide proper management, in turn helping to optimise the maintenance cycle, the boil of gas and reduce risk in emergency situations.

About us

Ascenz Marorka, a GTT company, is a leading provider of digital solutions for Smart Ships in the maritime industry, offering one of the most comprehensive, innovative and reliable digital platforms for ship owners and charterers around the world.

GTT is a technological expert in containment systems with cryogenic membranes used to transport and store liquefied gases. For nearly 60 years, GTT has been designing and providing cutting-edge technologies for a better energy performance, which combine operational efficiency and safety, to equip LNG carriers, floating terminals, land storage, and multi-gas carriers.